Often, you’ll hear praise for German or Japanese machinery. Our mission is to demonstrate that American engineering leads the world in excellence. The projects below highlight our machines, designed with precision and performance that surpass all global competitors!

ASSEMBLY AND BRAZING MACHINE:

This machine is one of its kind, the real pride of American engineering! High precision assembly and brazing machine, making special aerospace drill assemblies. It is a fully automated lights-out system. It successfully assembles parts within a 0.0002″ window (0.0001″ per side).

Machine capacity is 600 parts, enough for several hours of unattended run. Cycle time depends on the drill diameter. For a 1/8″ drill and quick disconnect adapter, the cycle time is 45 seconds per part. Currently, the machine runs at a 99.9% yield, which is exceptional.

In-line quality control is optional and can include: torque testing, height testing, runout testing.

This system can be utilized for female/male assemblies other than drill/adapter. The standard machine covers male parts up to 3/8″ and female parts with OD up to 5/8″. Larger diameters are optional.

When it comes to the joining process, we can offer: adhesive gluing, soldering, brazing, and TIG welding. Press fit can be quoted as an option.

SERVO PUNCHING PRESS:

A unique application to punch a custom profile into PE plastic parts. The die set is run by a Servo Actuator, and all the tools are precision-made using D2 tool steel. Tools are interchangeable within 0.0001″. The clearance between punch and die is 0.0002″. This unique machine featured machine design excellence by working after assembling and programming without a single day of debugging.

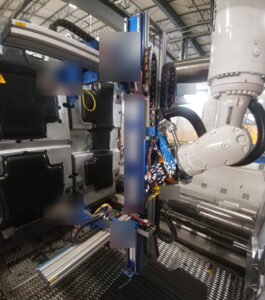

HYDRAULIC PUNCHING PRESS MACHINE TENDING CELL:

Machine-tending robotic cell. Machine punches small and precise profiles on the 5mm diameter 300mm long round tube. Tube infeed accumulation is over 1000 tubes, and proper separation and singulation was one of the main challenges during project execution.

Robot is the main material handling device on this machine. It does quick swap out of the tubes to maximize utilization of the punch press.

The press itself was handed over to CITC by customer and a third party press was successfully integrated into our system.

STANDARD AUTOMATION SYSTEMS FOR THE THERMOFORMING INDUSTRY

While we often design and build custom automation machines, do we do offer several standardize lines of product. One of them is automation for All Weather Mat Injection Molding industry.

Automation Systems we offer for this industry are:

- IMM Automation – Placing overmold logo inserts in injection molding machine and taking finished mats out.

- IMM Universal EOAT – Robot EOAT specifically designed to handle various floor mats without EOAT changeover. Fully adjustable.

- IMM Robot Calibration System – Calibration system which automatically aligns robot coordinate systems with IMM tooling plate

- Vehicle Logo Assembly Press – Semi-Automated Press that can accept any kind of tooling to assembly vehicle manufacturer logo on the floor mat.

- Grommet Assembly Machine – Automated system that can automatically install locking grommets on the floor mat.

ALL WEATHER FLOOR MAT – IMM AUTOMATION:

Injection Molding Machine Robotic Tending Cell.

1300 ton Krauss Maffei. Fully integrated KUKA Qunatec Robot. 2-story platform. Automated conveyor system. Dedicated tool changeover area. Operator work station one the 1st level with conveyor controls.

ALL WEATHER FLOOR MAT – UNIVERSAL ROBOT END OF ARM TOOLS:

We designed and developed a Universal EOAT, capable of picking any floor mats out of IMM. Tested on multiple robot cells. Exceptional performance.

ROBOT TO IMM CALIBRATION TOOLS :

We designed and built calibration tools that can quickly and accurately alight robot with injection molding machine tool plate.

ALL WEATHER FLOOR MAT – CUSTOMER LOGO ASSEMBLY PRESS:

This pneumatic press has capability of snapping together end user logo molds and and their retaining features. Machine has advance safety system and is capable of quick change over and position adjustments. Very universal for many various logos and mats.

ALL WEATHER FLOOR MAT – GROMMET ASSEMBLY MACHINE:

This multi-axis machine can handle 30+ various floor mats and multiple retaining grommets. It is manually loaded, one by one floor mat, but could be upgraded with fully automatic robotic infeed.

STANDARD AUTOMATION SYSTEMS FOR THE THERMOFORMING INDUSTRY

Another standardize line of product is Thermoforming Automation.

Automation Systems we offer for the Thermoforming industry are:

- Flat Sheet Thermoforming Automation – These systems offload pre-cut pieces from flat sheet thermoformers like Sencorp White, Brown and others. In Flat Sheet Thermoforming Automation, we have 3 layouts:

- Left Hand Layout

- Right Hand Layout

- Double Side Layout

- Cup In The Box Packaging Automation

- Trim Press Automation

- Trim Press Vision Inspecting Systems

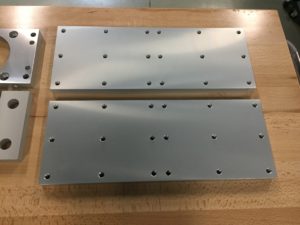

VARIOUS MACHINED PARTS

VARIOUS MACHINED PARTS

VARIOUS MACHINED PARTS

Free Consultation

Please reach out to us for 1/2h of free consultations.